MULTIPLE PROCESSES

We have three production units dedicated to decoration, which manage all of our finishing operations.

The list of services we offer is huge and non-exhaustive: screen printing (enamel, organic, precious metals), pad printing, decal printing, satin finishing, sandblasting, setting various accessories and savercoat spray coating, which involves colouring and satin-finishing the glass using a patented organic process, etc.

| ENAMEL SCREEN PRINTING | |

|

A process that enables enamels to be printed onto bottles using a screen. The production resources are automated. The decorable surfaces must generally be developable. Key advantages of enamel screen printing : Access to a very wide range of colours |

|

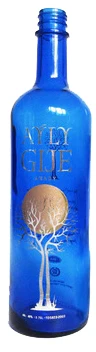

PRECIOUS METALS SCREEN PRINTING |

|

|

A process that enables precious metals to be printed onto bottles using a screen. The production resources are automated. The decorable surfaces must generally be developable. Key advantages of precious metal screen printing :

|

|

ORGANIC SCREEN PRINTING |

|

|

Decoration process that uses organic inks. Key advantages:

|

|

ACID-ETCHING |

|

|

This gives glass a dull or frosted effect and changes its texture. It is achieved by soaking in a bath of nascent hydrofluoric acid. The satin-finishing can be either full or partial, through application of a mask before the satin-finishing process.

Key advantages :

|

|

ACID-ETCHING WITH WINDOW |

|

|

This gives glass a dull or frosted effect and changes its texture. It is achieved by soaking in a bath of nascent hydrofluoric acid. The satin-finishing can be either full or partial, through application of a mask before the satin-finishing operation.

Key advantages :

|

|

SANDBLASTING |

|

| Sanding gives glass a frosted appearance. The texture can be more or less rough, depending on the grade used. Sandblasting reserves can be created, enabling patterns and insets to appear in specific areas of the bottle. |  |

TOTAL PRINTED |

|

|

The process offers a wide variety of colors and surface finish (glossy, matte, satin, etc.). It is fully eco-compatible because it uses water-soluble products.

Key advantages:

|

|

PARTIAL PRINTED |

|

|

The process offers a wide variety of colors and surface finish (glossy, matte, satin, etc.). It is fully eco-compatible because it uses water-soluble products.

Key advantages:

|

|

METALLIZATION |

|

|

This technology allows to create an upmarket package with an individual look. The glass is transformed into metal thanks to a fine metallic coating applied either totally or partially. Resulting in either a brilliant or matt aspect, in a myriad of metallic colors.

Key Advantages :

|

|

HOT STAMPING |

|

|

The object is to print a « film », i.e. a length of PET tape coated with fine layers of aluminium with a variety of aspects : gold, platinum, brilliantly coloured, satin-smooth or matt. This film is applied by direct stamp or by unwinding. Beforehand, the glass must be screen printed with an ink that will allow the film to adhere to the glass.

Key advantages :

|

|

TRANSFERS |

|

| Decals are images generally made up of several colours, in enamel or precious metals. They are produced by flat screen printing. They are laid by hand, after soaking in water, or automatically by transferring the image using a silicon pad. They enable those areas to be reached that cannot be screen printed in multiple colours, for which a greater tracking precision is required. |  |

SETTING ACCESSORIES |

|

|

This involves the automated or semi-automated setting of wax, metal, glass or plastic stamps, or any other accessory that enhances the product.

Key advantages :

|

|